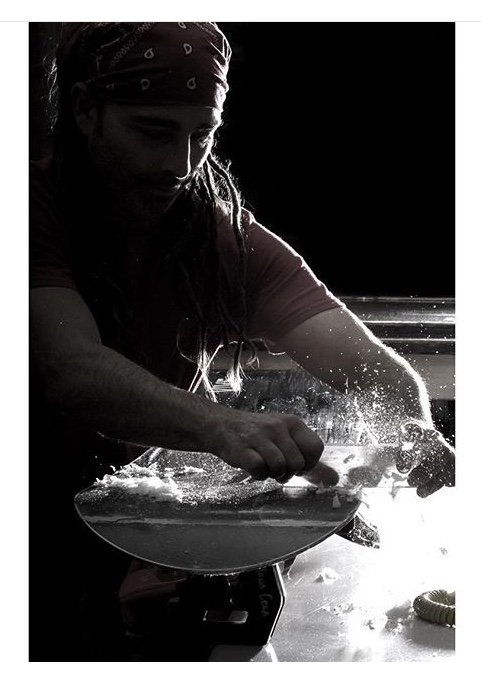

The majority of riders don’t think too much about board tuning, the majority will fill gouges with p-tex when we hit a rock and give it a wax when it looks a little dry but some people rarely even do that. So what about the pros that require their boards to ride at their optimum to ensure they have enough speed to clear a slow kicker knuckle and boost that little bit higher out of the lip? Ryan Mcdermott has become the pros favourite board technician and when he’s not tuning boards in his Colorado based Mono Cera Tuning shop, you can find him at the biggest contests making sure the riders boards are working as they should.

I know a lot of people that rarely, if at all wax their boards. Does it ever frustrate you to see riders on boards that they don’t look after?

This is an Awesome Question! Nah, not at all! I know how it is, I never looked after my own board, before I started Tuning or had access to a Shop. I just couldn’t be bothered putting the time in when you could be out shredding instead! Tuning your board definitely can make for a better ride though and definitely benefits riders competing at such a high level.

Tuning boards is more complex than melting some wax on and iron and scraping it off, how long has it taken you to learn the craft of tuning to such a high level?

Yeah, there’s a lot that goes into it, but if that’s all you can do then that’s a great start! I think that I’m still learning all the time, or at least I like to believe that. There’s definitely occasions when you feel challenged and you just have to rely on the experiences you’ve had and what people have passed on to you! Sometimes it’s as simple as patience and waiting for a rider to give you the feedback. I’m definitely NOT the best Tech that I know, I just feel like the best I can do is keep an open mind and give the best effort based on the experiences I’ve had or am having with the riders. They deserve that, contests or just Free Riding.

You are originally from Boston before settling in Colorado, how did you get started tuning boards and did you ever think it would give you the opportunity to travel so much as you do?

In 1996, I had made a trip out to Colorado to see some friends and that was my first introduction to Tuning. I fell in love with the mountains and kinda knew it wouldn’t be long before I was living in them. I started Tuning, just waxing skis and boards. I guess that puts me somewhere near twenty years doing it?! In that span I’ve been lucky enough to have worked under some really good techs and really Great people, like Tim Assor, Luke Byers, Dean Furth (Snowboard Workshop, Queenstown, NZ), Jared Hawn and Rick “Pup” Ascher.

I started by working in a little shop for some extra scratch during University, after a trip out West. I just really liked working on skis and boards and getting a chance to head up to Maine, New Hampshire and Vermont! When I got into riding, it was perfect because not a lot of the Techs really worked on boards at the shop. I had a few years tuning alpine skis for recreation and races but learned a lot from working on cross country skis. A year or so after University, I moved out to Summit County, Colorado. When I got there I was really fortunate to work for Franklin Crowe, who was tuning at all the Grand Prix’s, Vans Triple Crown, The X-Games, and The ’06 Winter Games. I learned a ton through his Shop, repairs, base grinding, edge work, which wax to work for which conditions and then he started bringing me to some events. That’s when I started tuning mostly boards for friends and some competitors. Not long after that I had reconnected with Kenny Nault, who’s a Legend and really the Tech that took tuning on the contest circuit to the level it’s at today, he’s the guy that gave me a real opportunity to work at the highest competition levels, and for that I’m thankful!

I could never have imagined that I would have travelled as much as I have for tuning! I’m like any kid, I just wanted to Snowboard as much as I possibly could and that hasn’t changed! The Tuning thing was an “ends to a means” and with time there became more opportunities to work with riders at events around the globe. Sometimes you find yourself Tuning way more than riding and that’s when it’s important to remember why you got into it in the first place.

You have tuned boards for Jamie Anderson, Shaun White, Danny Davis, Scotty James and countless others, what kind of tuning do those require compared to your average weekend warrior snowboarder?

The concept of the Tune is the same for the “Weekend Warrior” and pro shreds! When my partner Chip Proulx and I are at our shop based “Mono Cera Tuning Shop” and dialling in boards, some of it is based on level at which the rider is at, but for the most part I’d like to think that all Shops are trying to increase the glide ratio of the base of the board over the snow the rider will be on, whether its just travel, recreation, or competition.

Treating the bases of snowboards with wax by ironing wax into the base is the main way we increase the glide ratio of the base over the snow conditions, but we also introduce structure into the base as well. When our boards travel over the snow, the friction created by the speeds travelled over snow actually transfers the crystals of ice in the snow into minute beads of water. The beads of water that form between the surface to the base and the surface of the snow can create “surface tension”. This surface tension can slow your ride. That’s why we introduce structure into the base of our boards, the structure acts very much like the treads on a car’s tire and moves the excess water molecules from underneath the board. We add temperature specific waxes in order to “repel” the minuscule water beads and essentially create and this is kind of mind blowing! “liquid ball bearings” for the board to move over. We’ll Introduce super hard waxes to protect the bases from very abrasive ice crystals in the snow during extremely cold temperatures. Structure plays a huge part in treating our bases for better glide, but if you’re waxing you’re already taking a step to ensure that you’ll have a better day on the Mountain.

As for your edges, it’s all really personal preference! Some riders like them sharp and some riders like them knocked back or what we refer to as “detuned”. Sharp edges are usually preferred for pipe and large park jumps. Detuned, to preference, usually benefits park riders that session jumps and rails. In some situations, we’ll change the bevel (fancy word for “angle”) to make the edge “bite” better into harder snow, i.e. pipe walls. As a Tech, we try to leave as much of the board the way the manufacturer has designed it for its best ride. We’re just personalising the tune for each rider as best we can. I like to think that this comes from listening to the riders and that relationship hopefully allows us to provide them with the Tune that benefits them and their board most!

For competition riders we usually have to take into account each riders’ preferences and what they’re riding. Time is also crucial. The pros only get so many days on course to figure out the run that works best for them, so the board has to perform from “jump street”. After we come up with a structure we feel will run best at each event, we dial in the edges to the rider, and then we wax for days! Once the base is infused, it puts us in a better place to make a “wax call” heading into the actual Event.

The weather can change pretty quickly on the hill, how frustrating is it if you service a fleet of boards and the conditions change, do you have to start the entire process again?

By taking the time to prep boards, structuring bases, setting edges, and infusing bases with wax, we’re kind of preparing the boards for changes that may and do occur. As Techs, we’re super fortunate for the work that builders put into the parks! The parks have evolved so much and have so much speed generated by the features alone, that it’s half the battle. That being said, we always prepare for the worst conditions. You tend to become a closet meteorologist of sorts. Checking all the weather sites, the mountain’s websites and webcam feeds. One of the best resources is asking the locals and local shops about the snow and wind trends. Then at the last moment, you make your wax call for the next day, recreation or event.

On the mountain, techs carry bags with all sorts of gear: binding hardware, straps, buckles, screwdrivers, shanks, brushes for excess wax, scrapers, and more. Most importantly, we carry pretty expensive waxes, which we call “Overlays”. These overlays are pretty much “band aids” for changes to the course, whether natural or man made. If the Snow gets warm and breaks down, we usually got an overlay for it. If the wind draws the moisture from the snow crystal and the snow gets harder, we usually got an overlay for it. If the lips of the jump start to get soft and park crew has to salt them, we usually have an overlay for the salt!! 99% of this relies on the feedback of the rider. The riders can tell you, almost intuitively, if the course is slowing or getting faster and what’s causing it. Then the Tech needs to try to solve it and get out of the way. There is also the anomaly of too much wax in a board. This is actually the reason a board is Slow in the majority of the circumstances. That’s when you see a Tech brushing the base of the board frantically. All in all, most the work is done the weeks and ultimately the night before with the proper preparation.

Do you feel that if a rider can’t afford a wax tech they have a disadvantage to the riders that can?

This is a hard one to answer due to a couple of factors. First, the riders at these events are so insanely talented and that’s 90% of the equation. Second, variations in course conditions due to weather changes, really tend to level the field of competition and thirdly, some of the riders without Techs are actually really good technicians themselves! Torstein Horgmo and Chas Guldemond are probably better Techs than I am! Roope really knows how to tune too! Seriously, some riders are just really in tune with their gear and want to have their hands on it, kind of part of the process sort of thing, I dig it!

There is an advantage to having a Tech. I mean, that’s all I do. So that alone saves a rider some time that they could be getting some rest, a good meal, a Skate or even some physio work. Honestly though, the Snowboard community is pretty tight, and no one wants to see a rider struggle because their board is letting them down. If I see a rider having a tough day on course during an event, I’ll definitely offer whatever assistance I can, and the other riders are quick to get each other’s back! That may be the advantage, having your board professionally tuned, structured, edge set, wax infused etc, through a Tune shop can definitely help to ensure riders’ boards are in a better place come contest time. My Shop in Summit County is open to anyone just for these reasons.

Have you ever been responsible for a rider not being able to complete a run due to using the wrong kind of wax and if so what happened?

Absolutely not haha! Uh, I’m sure I have and your heart just sinks! That reoccurring dream or better nightmare where you hit a jump and you just knuckle, over and over, or worse you just send it way past the tranny and start rolling down the windows, preparing to absorb the flats. Yeah, that feeling hits you in the chest like a punch! Again, courses change up in literally the time it takes for a riders to go full pull on one run, to knuckling jump two on the next. It can be the time of a chairlift ride or a Mach 2 ride on a sled back up to the start. As soon as you see it, or get feedback from the rider, you damn well better have a solution. It’s a shit feeling and that’s what makes you work so hard in the preparation process. That’s why you see techs up late at night and sometimes up super early to change out waxes, due to weather changes.

I remember Torstein coming up a little short at the Dew Tour in Breck in 2010. It just started dusting snow and the course slowed down a lot! He wasn’t stoked and he let me know! I was heartbroken and really felt like I let him down. But you don’t have time to waste., I came up with what I thought was a Solution and he destroyed it and won. I know that it was literally 99% his skill, but he was super cool afterwards. I’ll tell you, that moment made us good friends and made me a much better Tech.I don’t leave anything to chance, the riders deserve everything you got.

You have travelled far and wide tuning boards what is the best place you have travelled to and why?

Wow, this is a tough one! I was just lucky enough to spend almost three weeks in Norway!!! It’s Rad! The People are great and the mountains and Fjords are Insane! I will be back! All the places that I’ve been fortunate to head too through Tuning, it’s really hard to narrow to one, but Laax, Switzerland! I’ve gotten it so good and the people are awesome, the Mountain is insane! It’s an easy drive through nice Country up to mountain too, I’d like to spend some real shred time there! I’ve never been to japan, yet!

You can find Ryan and his Mono Cera Tuning Shop Website here.